HAL STM32F1 通过查表方式实现SVPWM驱动无刷电机测试

HAL STM32F1 通过查表方式实现SVPWM驱动无刷电机测试

- 📍相关篇《基于开源项目HAL STM32F4 +DSP库跑SVPWM开环速度测试》

- ✨针对STM32F1系列,硬件上没有可用的浮点单元(FPU),为了实现特定函数的浮点运算快速计算,通过查表方式来实现,以空间换速度的方式。

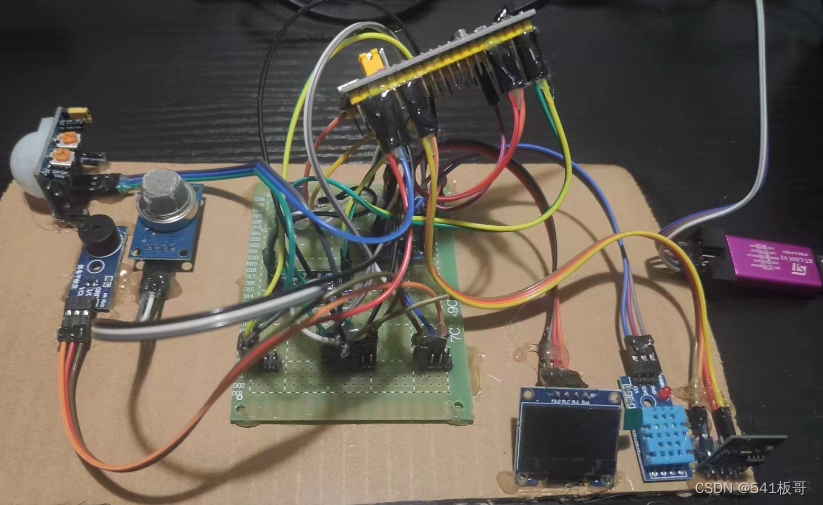

- 📍硬件电路和项目参考,立创开源广场:

http://oshwhub.com/shadow27/tai-yang-neng-wu-ren-chuan - 📌 采用6路驱动控制,可以参考个人的相关篇《自制无感无刷电机驱动板》

📘实现核心代码

- 📑

svpwm.c

#include "tim.h"

#include "svpwm.h"

#include "stdio.h"

#define PWM_Period 4800

float voltage_power_supply=12; //母线电压12V

float sensor_offset=0;

float zero_electric_angle=0;

float _normalizeAngle(float angle)// 标准化角度 [0,2PI]

{

float a = fmod(angle, _2PI); //fmod()对浮点数取模

return a >= 0 ? a : (a + _2PI);

}

//把0~Π/2的正弦值分成200份

const int sine_array[200] = {0,79,158,237,316,395,473,552,631,710,789,867,946,1024,1103,1181,1260,1338,1416,1494,

1572,1650,1728,1806,1883,1961,2038,2115,2192,2269,2346,2423,2499,2575,2652,2728,2804,2879,2955,3030,

3105,3180,3255,3329,3404,3478,3552,3625,3699,3772,3845,3918,3990,4063,4135,4206,4278,4349,4420,4491,

4561,4631,4701,4770,4840,4909,4977,5046,5113,5181,5249,5316,5382,5449,5515,5580,5646,5711,5775,5839,

5903,5967,6030,6093,6155,6217,6279,6340,6401,6461,6521,6581,6640,6699,6758,6815,6873,6930,6987,7043,

7099,7154,7209,7264,7318,7371,7424,7477,7529,7581,7632,7683,7733,7783,7832,7881,7930,7977,8025,8072,

8118,8164,8209,8254,8298,8342,8385,8428,8470,8512,8553,8594,8634,8673,8712,8751,8789,8826,8863,8899,

8935,8970,9005,9039,9072,9105,9138,9169,9201,9231,9261,9291,9320,9348,9376,9403,9429,9455,9481,9506,

9530,9554,9577,9599,9621,9642,9663,9683,9702,9721,9739,9757,9774,9790,9806,9821,9836,9850,9863,9876,

9888,9899,9910,9920,9930,9939,9947,9955,9962,9969,9975,9980,9985,9989,9992,9995,9997,9999,10000,10000};

//0~360°的正弦值,函数通过使用固定大小的数组来逼近正弦计算

float _sin(float a){//a的值最大为2Π,即6.28318530718

if(a < _PI_2){//a<1.57079632679

//return sine_array[(int)(199.0*( a / (_PI/2.0)))];

//return sine_array[(int)(126.6873* a)]; // 浮点数组优化

return 0.0001*sine_array[_round(126.6873* a)]; // int数组优化

}else if(a < _PI){//1.57079632679<=a<3.14159265359

// return sine_array[(int)(199.0*(1.0 - (a-_PI/2.0) / (_PI/2.0)))];

//return sine_array[398 - (int)(126.6873*a)]; // float array optimized

return 0.0001*sine_array[398 - _round(126.6873*a)]; // int array optimized

}else if(a < _3PI_2){//3.14159265359<=a<4.71238898038

// return -sine_array[(int)(199.0*((a - _PI) / (_PI/2.0)))];

//return -sine_array[-398 + (int)(126.6873*a)]; // float array optimized

return -0.0001*sine_array[-398 + _round(126.6873*a)]; // int array optimized

} else {//4.71238898038<=a<6.28318530718

// return -sine_array[(int)(199.0*(1.0 - (a - 3*_PI/2) / (_PI/2.0)))];

//return -sine_array[796 - (int)(126.6873*a)]; // float array optimized

return -0.0001*sine_array[796 - _round(126.6873*a)]; // int array optimized

}

}

//0~360°的余弦值,函数逼近余弦计算使用固定大小的数组

float _cos(float a){

float a_sin = a + _PI_2;

a_sin = a_sin > _2PI ? a_sin - _2PI : a_sin;

return _sin(a_sin);

}

//近似开根号函数

float _sqrtApprox(float number) {//low in fat

long i;

float y;

// float x;

// const float f = 1.5F; // better precision

// x = number * 0.5F;

y = number;

i = * ( long * ) &y;

i = 0x5f375a86 - ( i >> 1 );

y = * ( float * ) &i;

// y = y * ( f - ( x * y * y ) ); // better precision

return number * y;

}

// 输入参数0.0f ~ 1.0f,输出3路PWM

//void Set_PWM(float _CCR1, float _CCR2, float _CCR3)

//{

// __HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, _CCR1 * PWM_ARR);

// __HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_2, _CCR2 * PWM_ARR);

// __HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_3, _CCR3 * PWM_ARR);

//}

//FOC核心函数:输入Ud、Uq和电角度,输出PWM

void setPhaseVoltage(float Uq, float Ud, float angle_el)

{

float Uref;

uint32_t sector;

float T0,T1,T2;

float Ta,Tb,Tc;

float U_alpha,U_beta;

angle_el =_normalizeAngle(angle_el); //电角度标准化在【0,2pi】

U_alpha=Ud*_cos(angle_el)-Uq*_sin(angle_el); //反park变换

U_beta=Ud*_sin(angle_el)+Uq*_cos(angle_el);

Uref=_sqrtApprox(U_alpha*U_alpha + U_beta*U_beta) / voltage_power_supply;

if(Uref> 0.577)Uref= 0.577; //六边形的内切圆(SVPWM最大不失真旋转电压矢量赋值)根号3/3

if(Uref<-0.577)Uref=-0.577;

if(Uq>0)

angle_el =_normalizeAngle(angle_el+_PI_2); //加90度后是参考电压矢量的位置

else

angle_el =_normalizeAngle(angle_el-_PI_2);

sector = (angle_el / _PI_3) + 1; //扇区判断

//每个扇区中两个相邻电压矢量Uref作用时间

T1 = _SQRT3*sin(sector*_PI_3 - angle_el) * Uref;

T2 = _SQRT3*sin(angle_el - (sector-1.0)*_PI_3) * Uref;

//零矢量作用时间

T0 = 1 - T1 - T2;

switch(sector) //计算各相的作用时间

{

case 1:

Ta = T1 + T2 + T0/2;

Tb = T2 + T0/2;

Tc = T0/2;

break;

case 2:

Ta = T1 + T0/2;

Tb = T1 + T2 + T0/2;

Tc = T0/2;

break;

case 3:

Ta = T0/2;

Tb = T1 + T2 + T0/2;

Tc = T2 + T0/2;

break;

case 4:

Ta = T0/2;

Tb = T1+ T0/2;

Tc = T1 + T2 + T0/2;

break;

case 5:

Ta = T2 + T0/2;

Tb = T0/2;

Tc = T1 + T2 + T0/2;

break;

case 6:

Ta = T1 + T2 + T0/2;

Tb = T0/2;

Tc = T1 + T0/2;

break;

default: //其他情况关闭上管,打开下管,即刹车

Ta = 0;

Tb = 0;

Tc = 0;

}

//printf("[Ta,Tb,Tc]:%f,%f,%f\r

", Ta, Tb, Tc);

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, Ta*PWM_Period); //输出U相PWM,配置占空比

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_2,Tb*PWM_Period); //输出V相PWM,配置占空比

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_3, Tc*PWM_Period); //输出W相PWM,配置占空比

}

- 📄

svpwm.h

#ifndef __SVPWM_H__

#define __SVPWM_H__

#include

#define _sign(a) ( ( (a) < 0 ) ? -1 : ( (a) > 0 ) )

#define _round(x) ((x)>=0?(long)((x)+0.5):(long)((x)-0.5))

#define _constrain(amt,low,high) ((amt)<(low)?(low):((amt)>(high)?(high):(amt)))

#define _sqrt(a) (_sqrtApprox(a))

#define _isset(a) ( (a) != (NOT_SET) )

#define _2_SQRT3 1.15470053838

#define _SQRT3 1.73205080757

#define _1_SQRT3 0.57735026919

#define _SQRT3_2 0.86602540378

#define _SQRT2 1.41421356237

#define _120_D2R 2.09439510239

#define _PI 3.14159265359

#define _PI_2 1.57079632679

#define _PI_3 1.0471975512

#define _2PI 6.28318530718

#define _3PI_2 4.71238898038

#define _PI_6 0.52359877559

//FOC核心函数:输入Ud、Uq和电角度,输出PWM

void setPhaseVoltage(float Uq, float Ud, float angle_el);

#endif /* __SVPWM_H__ */

- 🌿在滴答回调函数中,每隔2毫秒执行一次

void HAL_SYSTICK_Callback(void)

{

// Sys_Tick_Count_1ms();

Count++;

if (Count >= vtaskms)

{

Count = 0;

//Uq和电角度增加值需要自己调,每个电机都不一样

setPhaseVoltage(0.5,0.0,angle_el); //空载的时候尽量让uq<2。Uq越大电机的电流越大,扭力约大

angle_el +=0.64; //估计电角度,电角度增加的越快,电机转的越快。电角度减小则电机反向旋转0.18 0.36 0.54 0.62

}

}

🎉在电机能转动的情况下,可以逐步增大电角度(

angle_el)数值,以提高转动的速度。在电机能提速的情况下,电流相对会减少。这个速度也不是不限增加的,当程序设定的角度电机执行完,正好与下一次循环设定的角度接近重合时,达到最佳的运转效果。

个人使用2204电机测试,在电角度参数和电机运转步进接近的状态下,空载下运转,电流只有60毫安左右,长时间运转,电机都没有感受发热。

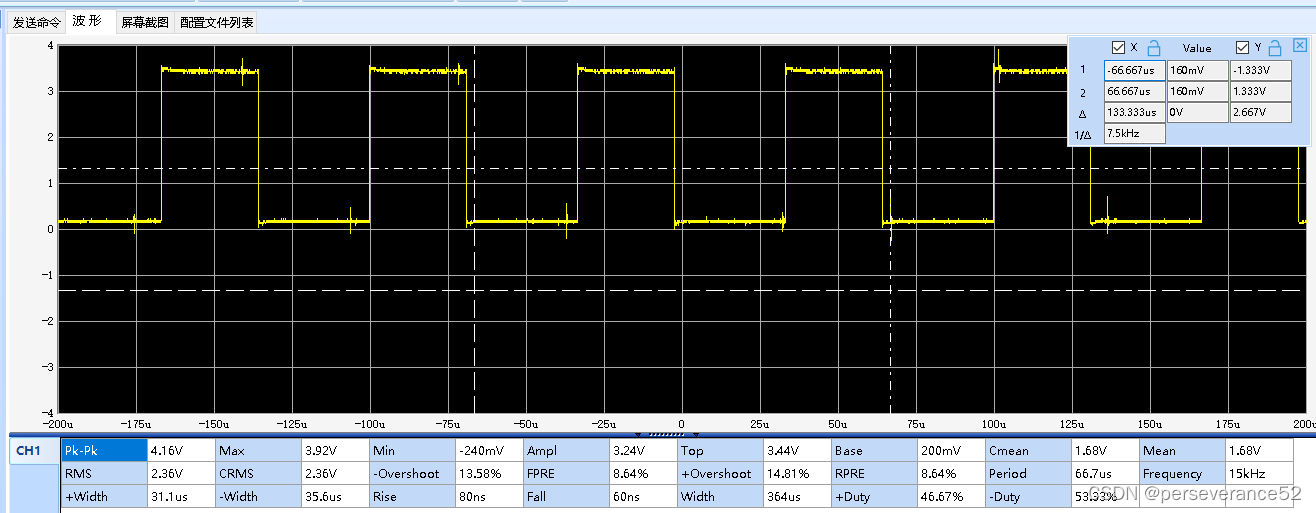

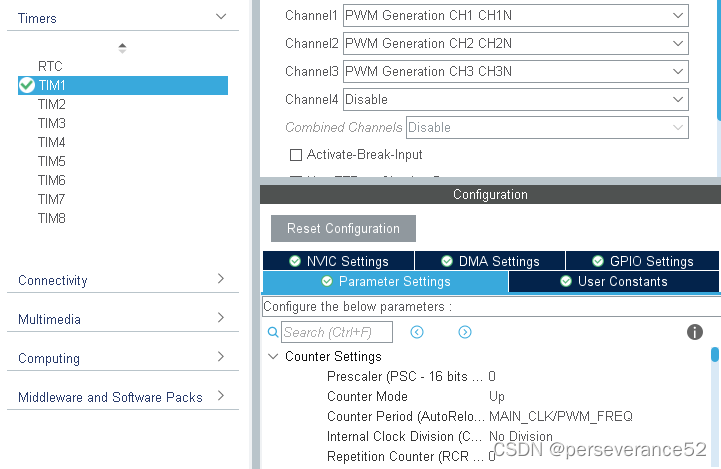

🌿3路PWM驱动波形及参数

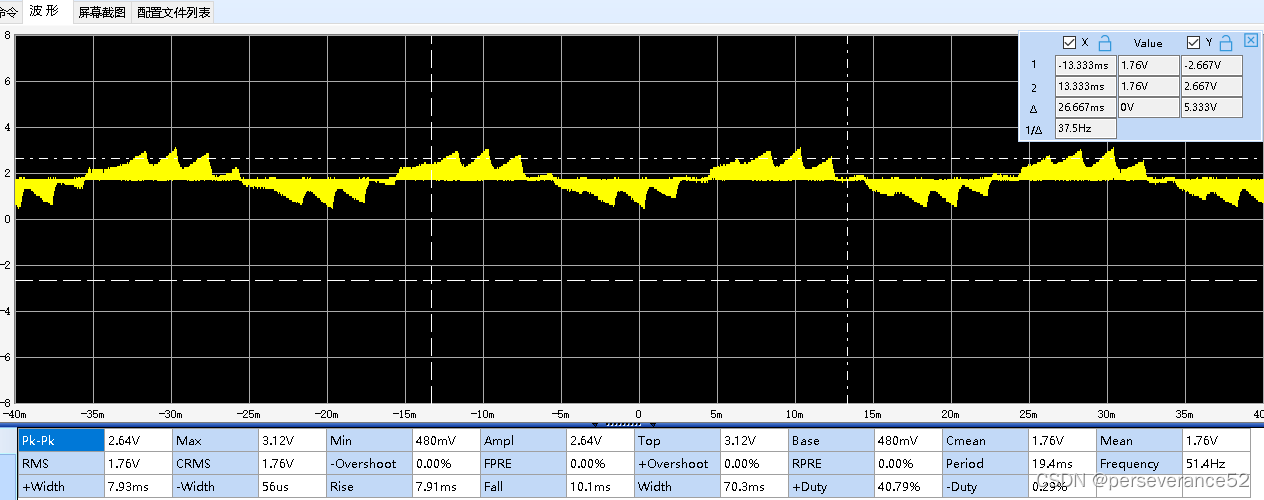

🌿三相驱动桥,下端电流采样波形

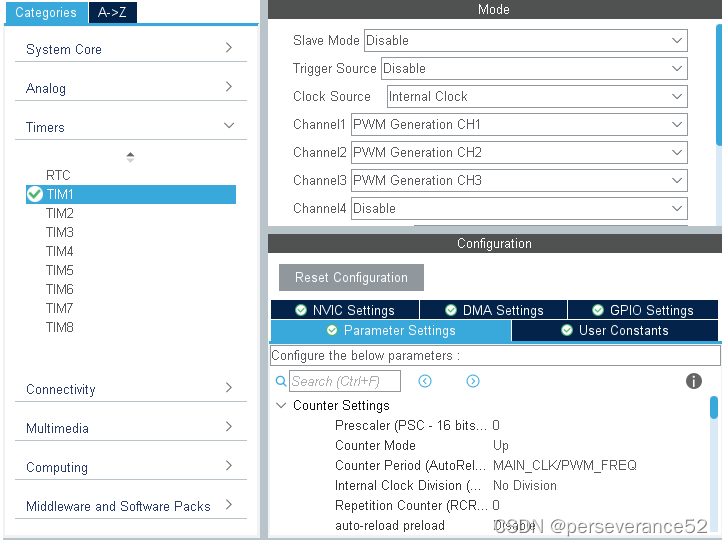

📚测试工程

- 🌿基于3路PWM控制。(EG2133)

链接:https://pan.baidu.com/s/1H_5o-4v7Z8x4XBi8RtVU1A?pwd=rcv6

提取码:rcv6

- 🌿基于3路互补PWM输出控制。

链接:https://pan.baidu.com/s/13mFTlaAbvnjr1eh-rdLQSQ?pwd=2fr7

提取码:2fr7